NEWS&EVENT

Quality is our core our concept

Application of aerogel/silica aerogel composites in the field of high-speed trains

Release time:

2024-08-20 00:00

Source:

Silica aerogel is a high porosity inorganic lightweight nano material with gas as the dispersion medium. Its own structure determines that it has a variety of unique excellent properties at the same time, such as low density, high porosity, high specific surface area, low refractive index, low thermal conductivity and low dielectric constant. In practical application, silica aerogels show the defects of brittleness and poor mechanical properties, and silica aerogels are hydrophilic due to the large amount of Si-OH on their surface, which can easily cause expansion and fracture of the skeleton structure after moisture absorption or water absorption, so they cannot be used alone. In order to make better use of the excellent characteristics of aerogels, silica aerogels can be processed into composite products by a variety of processes (immersion, hybrid compression molding, deposition, etc.). These composites have become new stars in the field of materials due to their ultra-low thermal conductivity, safety performance of inorganic materials, and excellent hydrophobicity and durability. With the rapid development of high-speed trains in China in recent years, the use of aerogel has provided new material support for breakthroughs in vehicle lightweight, noise control, comprehensive energy saving and other technologies, and has been initially applied to high-speed trains.

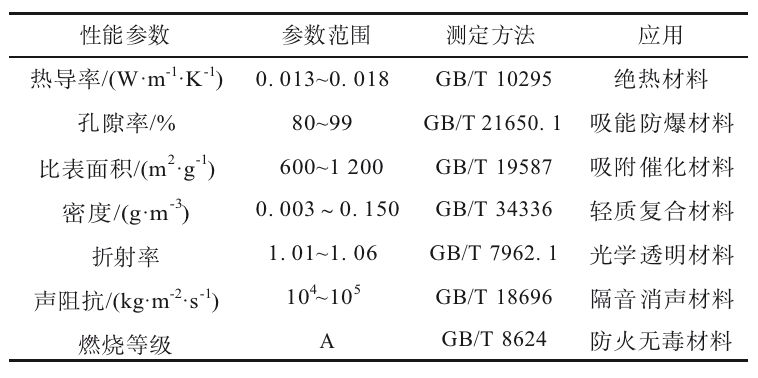

At present, silica aerogels are the most studied in the field of aerogels, and their production and manufacturing processes are relatively mature, which is also the most widely used oxide aerogels. Researchers have continuously attempted to select precursors, catalysts, aging processes, surface modification, and drying processes, ultimately obtaining porous nanosolid materials with highly cross-linked Si-O-Si chains and a three-dimensional skeleton structure in a gas medium. Table 1 shows the typical performance parameters and applications of silica aerogel.

Table 1 Typical performance parameters and application of silica aerogel

Silica aerogel

Thermal insulation, sound insulation, and flame retardant properties

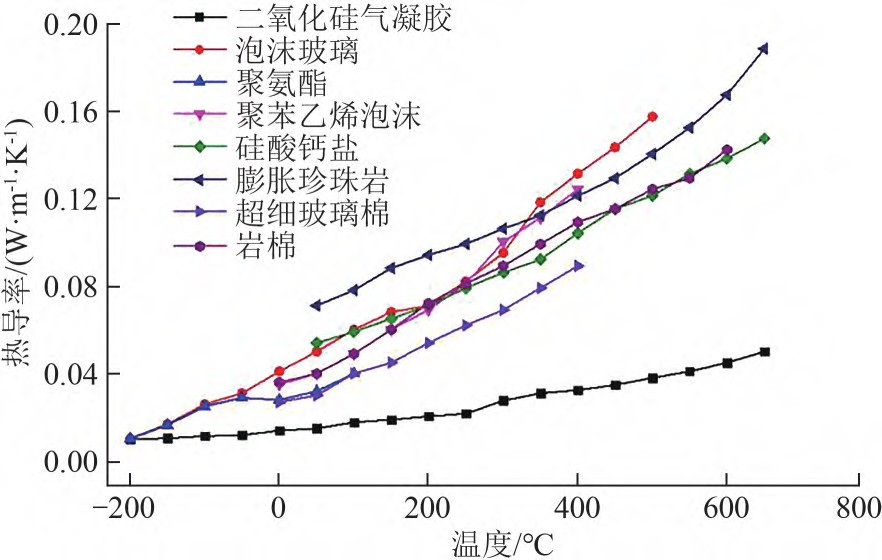

Due to the high specific surface area of silica aerogel, nearly infinite solid/gas interfaces are formed inside the material, and heat will reflect, absorb, transmit and re radiate at each layer of interface, thus reducing the thermal radiation. Table 2 shows the comparison of heat transfer modes of silica aerogel and ordinary porous materials. Figure 1 shows the comparison of thermal insulation performance between traditional porous thermal insulation materials and silica aerogel. It can be seen from the figure that the thermal insulation performance of aerogel is significantly better than that of traditional thermal insulation materials. Compared with other insulation materials, silica aerogel has the lowest thermal conductivity, lightest weight and higher heat resistance temperature. To achieve the same thermal insulation effect, the thickness of silica gas gel is less than 1/3 of that of traditional materials, with thinner thickness and smaller heat dissipation area, saving space to the maximum extent.

Table 2 Comparison of heat transfer modes between silica aerogel and ordinary porous materials

Figure 1 Comparison of thermal insulation performance between silica aerogel and traditional porous thermal insulation materials

Silica aerogel can be used as a lightweight sound insulation material for high-speed trains. When sound waves pass through pores, they are converted into thermal energy due to the friction between air and the skeleton. At the same time, sound waves reflect back and forth in the pores, causing string vibration of flexible silica aerogel framework, resulting in internal energy consumption, reducing sound pressure intensity, and achieving the effect of noise reduction. The extremely high porosity of silica aerogel makes it have ten times higher sound absorption effect than ordinary porous materials. At the same time, hydrophobic silica aerogel has good thermal stability and corrosion resistance, and still has good sound absorption performance in high temperature and harsh environment. At present, commonly used sound-absorbing materials such as asbestos and felt have limitations in terms of environmental protection, waterproofing, fire prevention, and lightweight. Silica aerogel gel can be used as a lightweight sound insulation material with both vibration and noise reduction and sound absorption capabilities.

The framework of silica aerogel is composed of three-dimensional O-Si network, which is bonded by Si and O elements, and has good flame retardancy. However, silica aerogels are hydrophilic, and their comprehensive performance declines after absorbing water in the air. Therefore, hydrophobic aerogels with surface modification are used in engineering. In order to ensure the use reliability of silica aerogels, the flame retardancy of hydrophobic silica aerogels is generally improved by changing the precursors and adding flame retardants. Combined with thermal stability analysis and flammability study, the following conclusions can be drawn: the flame retardancy of hydrophobic silica aerogels can be improved by using sodium silicate as the precursor and introducing phosphorus compounds such as phosphoric acid.

Silica aerogel

Types of composite materials

At present, silica aerogel gel is used as nanopore carrier in the world's reported nano mesoporous thermal insulation materials. However, the ultra light aerogels prepared by the existing process all have the disadvantages of low strength and poor toughness. At present, aerogel composites with high practical value are reinforced and toughened by various methods, such as precursor modification copolymerization, fiber reinforced materials and polymer cross-linking reinforcement.

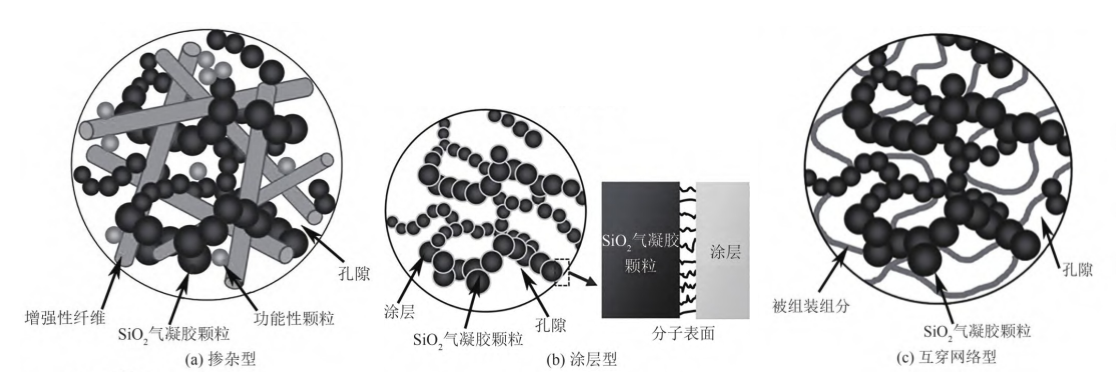

Silica aerogel composites can be divided into four categories: doped silica based aerogel composites, coated silica based aerogel composites, interpenetrating network silica based aerogel composites and combined silica based aerogel gel composites. The microstructure is shown in Figure 2. The combined silicon based aerogel thermal insulation composite is to combine the second phase materials in the form of doping, coating or interpenetrating network to give play to the advantages of the three composite modified materials, overcome the disadvantages, and form a composite with better comprehensive performance and better applicability.

Figure 2 Microstructure of silica aerogel composite

Silica aerogel composite coating

Application on high-speed trains

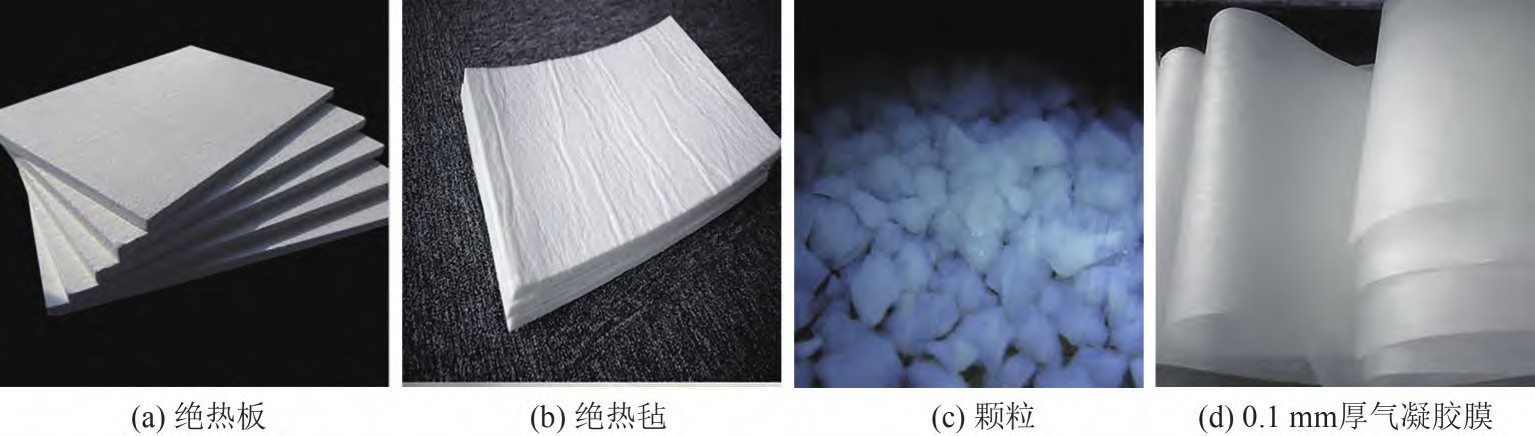

High speed trains are designed with high-performance materials such as insulation, fire and explosion prevention, vibration and energy absorption, sound insulation and noise reduction, due to the large changes in operating environment, high speed, and narrow compartment interlayer space. Silica aerogel composites have excellent properties such as light weight, heat insulation, sound insulation, flame retardant, hydrophobic and environmental protection, and have extensive potential application value in the optimization design of high-speed train body in the future. At present, the main silica aerogel composite products include thermal insulation board, thermal insulation felt, coating, film, particle, paper and profiled parts. Some composite products are shown in Figure 3.

Figure 3 Silica aerogel composite products

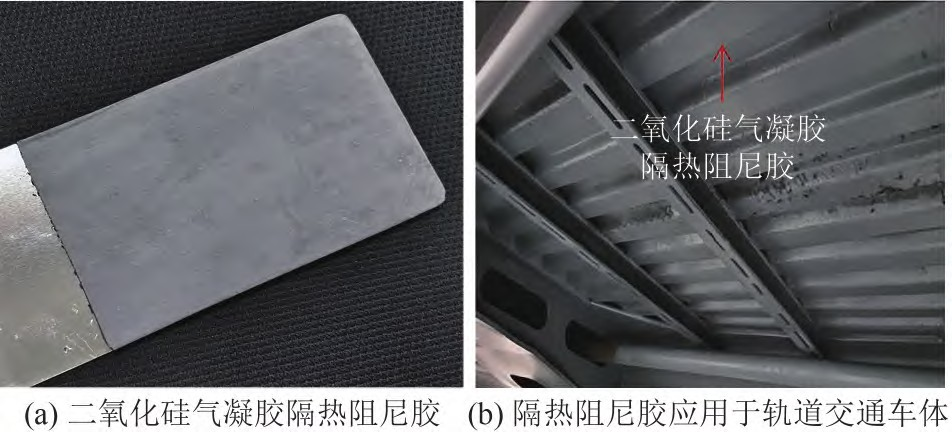

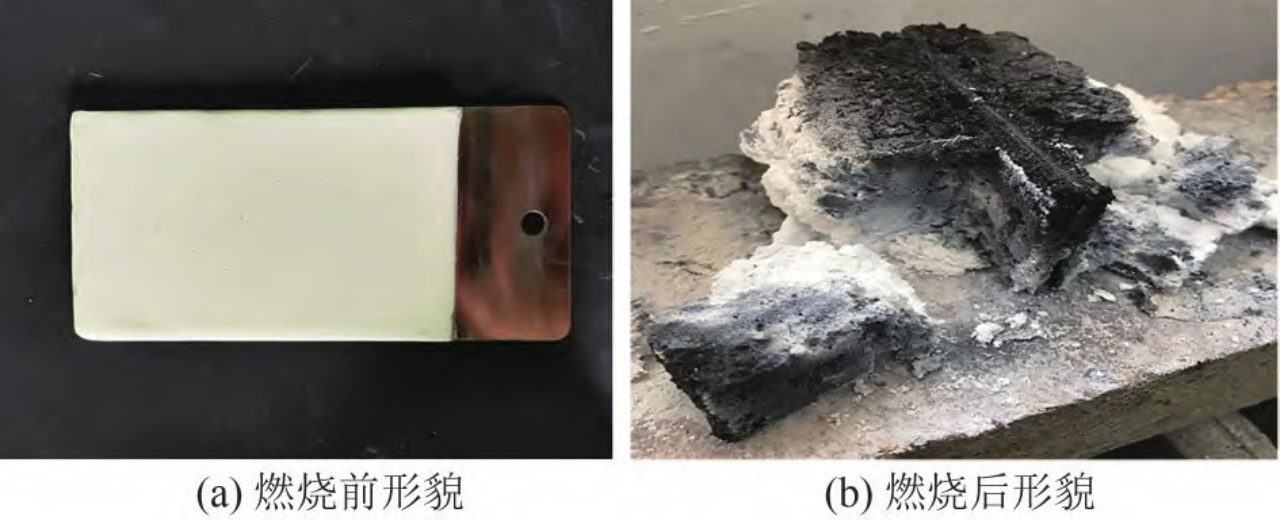

Silica aerogel composite coatings have different functions by using different characteristics of silica aerogel, and adding pigments, fillers, additives, etc. Figure 4 (a) is a damping adhesive compounded by silica aerogel powder with nano pore structure and high temperature resistant binder system, which is applied to the surface of metal plate of high-speed train body structure, as shown in Figure 4 (b). When the metal plate is excited and produces bending vibration, its vibration can be quickly transmitted to the tightly adhered damping coating. The damping coating converts the vibration energy into heat energy through internal displacement and friction, which plays a role in vibration reduction and noise reduction. Waterborne coatings can be prepared by dispersing silica aerogel in special high-performance resin lotion. Its performance parameters are as follows: thermal conductivity is 0 031 W/(m · K), density 120 kg/m3, flame retardancy V0 level, adhesion 1 2 MPa, with a hydrophobicity rate of not less than 98%. Coatings are effectively applied to the body of high-speed trains, achieving the goals of structural vibration reduction, noise reduction, thermal insulation, and surface protection, as well as thermal insulation in winter and summer, and reducing air conditioning energy consumption. Figure 5 shows the comparison before and after combustion of aerogel fire retardant coating for steel structure. The thickness of this coating is 3 At 0 mm, the fire resistance limit time reaches 2 hours (generally, the thickness of fireproof coating requires 3 5 mm); Strong adhesion to metal materials such as steel plates and aluminum plates, with a bonding strength greater than 1 0 MPa; After combustion, the metal sheet does not deform or burn, and is used to protect the load-bearing steel structural components of high-speed trains, effectively preventing the uncontrolled spread of fire.

Figure 4 Silica gas gel heat insulation damping adhesive and its application

Figure 5 Comparison of morphology of thermal insulation and flame retardant coating before and after combustion

Silica aerogel composite coiled material

Application on high-speed trains

The continuous acceleration of trains has significantly increased the noise inside the train. Currently, the interior wall panels and body of high-speed trains are generally filled with porous materials to form a composite sound insulation structure. Designers optimize the combination of porous materials, air layer thickness, and layered composite materials based on the transfer matrix method. The sound wave propagates in the framework network of aerogels. The energy of the sound wave is transferred and attenuated, and the amplitude and speed are reduced, making aerogels have low sound speed characteristics. Therefore, aerogels are ideal acoustic delay and high temperature sound insulation materials. By using silica aerogel composite coiled material, designers can reduce the overall mass of layered composite materials, reduce the use of porous materials, and achieve the design goal of low noise, lightweight, and low energy consumption.

The thermal conductivity of the existing silica aerogel composite coiled materials on the market is 1/5~1/3 of that of traditional materials, which effectively reduces the thickness of the insulation layer. The thermal conductivity increases slowly with temperature. The fire rating can reach Class A for building materials, and it does not produce smoke, droplets, or harmful gases under flames. The water repellency rate is not less than 99% 8%, moisture absorption rate not higher than 0 5%, with extremely strong waterproof performance, can avoid the problem of material settling due to water ingress, and does not need to be replaced even after long-term use. It has good resistance to heat erosion, can be cut arbitrarily, and is easy to install and use. The manufacturer can generally customize the product specifications according to customer needs. The technical parameters of silica aerogel insulation blanket are as follows: thermal conductivity 0.017W/(m · K), density 160kg/m3, tensile strength 1 409 MPa, hydrophobicity rate of 99 9%. Figure 6 shows the application of 5mm thick silica aerogel thermal insulation felt to the cold proof material structure in the flat roof area of a high-speed train. The closed coating treatment process has not only reduced the volume and quality of the structure, but also improved the cold proof and noise reduction effect.

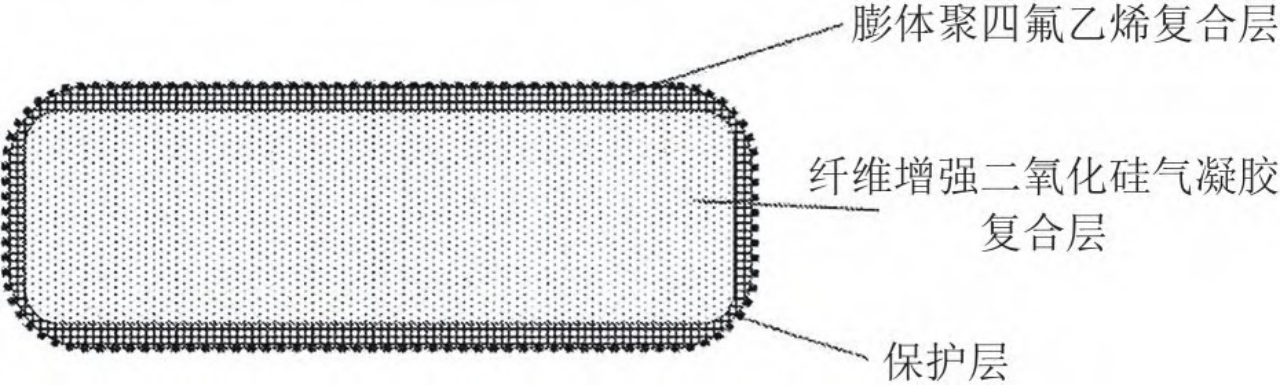

Silica aerogel is compounded with glass fiber, ceramic fiber or carbon fiber to obtain felt products. Although the heat insulation effect is good, the surface fiber is easy to break and pulverize, causing floating fiber or powder pollution. To solve this problem, the outer part of the aerogel composite layer can be covered with a layer of materials with higher strength and toughness, such as the composite layer of expanded polytetrafluoroethylene and flame retardant polyethylene terephthalate fiber, as shown in Figure 7.

Figure 6 Application of silica aerogel thermal insulation felt in high-speed trains

Figure 7 New silica aerogel insulation blanket

Silica aerogel composites

Other applications on high-speed trains

At present, the application of silica aerogel composites in high-speed trains has just started, and most of them are used as small auxiliary parts to meet the corresponding technical requirements. As the most promising new energy-saving and environmental protection material in the 21st century, silica aerogel composite is enriching the market with more products. In addition to the plates and coiled materials described above, silica aerogel glass, as a new energy-saving glass, also has many advantages, such as good heat insulation, sound insulation and noise reduction, wind pressure resistance, no hidden danger of cold and hot self explosion, good light transmittance, anti condensation, and service life of more than 30 years. The window area of high-speed trains (taking Fuxing as an example) accounts for 5% of the surface area of the train body About 8%. Due to the environmental changes during driving, these open areas have very high requirements for window glass. The silica aerogel glass has good comprehensive performance and has potential development value. In addition, as a new type of kinetic energy absorption material, silica aerogel has shown a broad application prospect in the field of energy absorption and buffer. The head of 350 km/h standard EMUs and intercity railway passenger cars are made of special explosion-proof and vibration damping materials. According to the existing test and research, silica aerogel composite materials also have development and application value in the special position of the head of high-speed trains.

Conclusion

This paper analyzes and introduces the structural and performance advantages of silica aerogel composites. Focusing on the requirements of high-speed train body lightweight, noise control, comprehensive energy conservation and safety fire prevention, and considering the characteristics of silica aerogel composites, such as light weight, heat insulation, sound insulation, flame retardant, anti-corrosion, vibration reduction, etc., silica aerogel composites, as an important green environmental protection new material, can provide new material support for the future development of high-speed trains. At present, the application of silica aerogel composites on train bodies is still in its infancy, and the comprehensive application of different performance advantages still needs continuous exploration.