NEWS&EVENT

Quality is our core our concept

Introduction to Aerogel

Release time:

2021-05-17 09:42

Source:

Hey, what is this?

Hey, what is this?

Like frozen smoke. This is not smoke, but a solid, specifically the world's lightest solid-aerogel.

What is aerogel?

First of all, let's get to know the "gel". A certain concentration of polymer solution or sol, under appropriate conditions, the viscosity gradually increased, and finally lost mobility, the whole system into a uniform appearance, and maintain a certain form of elastic semi-solid, this elastic semi-solid called gel.

Jelly is a kind of gel that was first recognized by scientists. This gel is formed when it is filled with water or other liquids. There are also some gels that are filled with gas, which is "aerogel". In 1931, American scientist Samuel StephensKistler prepared this new material, named "aerogel", aerogel. "Aero" "gel" describes the characteristics of this new material, namely a gel filled with gas.

Compared with ordinary porous materials, aerogels have an important feature: their skeleton is at the nanoscale. Therefore, when visible light passes through, it is less scattered and looks like "frozen smoke".

Aerogel has an extremely low density and is the lightest solid in the world. At present, the lightest aerogel is an "all-carbon aerogel" with a density of only 0.16mg/cm3 (air density removed), which is only 1/6 of the density of air. Put this material on the flower, the soft stamens are almost not deformed.

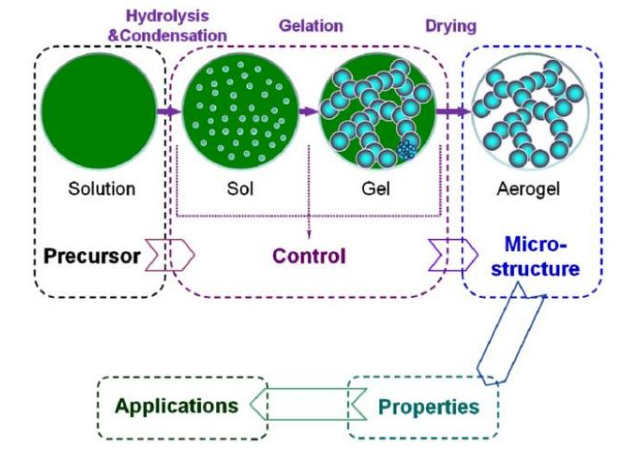

The preparation process of aerogel is divided into two steps: preparation of wet gel, drying of wet gel by special means. The most traditional method for preparing wet gels is the sol-gel method. The compound containing high chemical active components is dispersed in a solvent, and the active monomer is generated by hydrolysis reaction, and the active monomer is polymerized to form a sol, and then a gel with a certain spatial structure is generated. The gel produced at this time is somewhat similar to jelly, and the aerogel can be obtained by further drying the jelly-like gel. Due to the effect of surface tension, under normal conditions, the volatilization of the liquid in the gel will cause the fragile skeleton of the gel to collapse. Drying by freeze-drying technology can solve this problem. The wet gel was frozen at low temperature and then dried under vacuum. Since the freezing process has transformed the liquid in the gel into a solid, and then separated from the gel skeleton in the form of sublimation in a vacuum environment, the problem of skeleton collapse caused by liquid volatilization can be avoided, and the aerogel we expect is obtained.

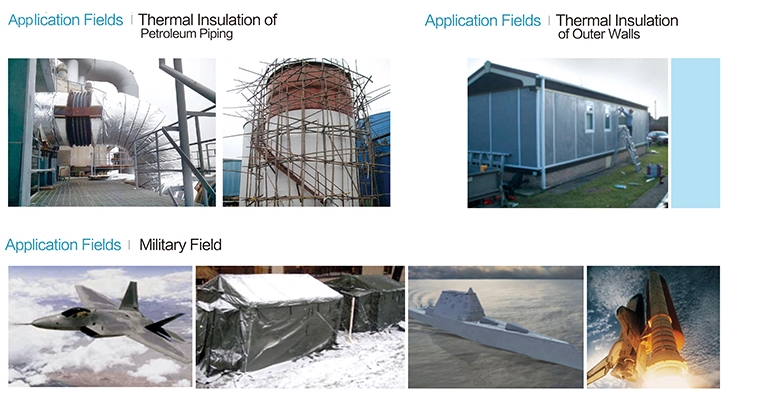

What is the use of aerogel?

I believe that everyone will have such doubts. The answer will also be various, "it has a very low thermal conductivity, can be used as a super insulation material" "it can be used as an electrode" "it can be used for pollution control". In general, the performance of aerogels is mainly contributed by two parts: one part is the structure, which is simply the performance derived from the porous nature, such as excellent thermal insulation performance. A flower is heated with a flame through the aerogel, and there is almost no damage to the flower. In addition, some aerogels also exhibit excellent adsorption properties, such as "carbon sponges". Aerogel can be made into thermal insulation felt, with soft, easy to cut, small density, inorganic fire prevention, overall hydrophobic, green environmental protection and other characteristics, is expected to replace glass fiber products, asbestos thermal insulation felt, silicate fiber products and other non-environmental protection, poor thermal insulation performance of traditional flexible thermal insulation materials. Existing oil absorption products generally can only absorb about 10 times their own quality of liquid, while the absorption of "carbon sponge" is about 250 times, up to 900 times. At the same time, the "carbon sponge" has high elasticity and can be restored after being compressed by 80%. This makes it easy to think of using it to deal with oil spills at sea. Sprinkle them on the sea to quickly absorb the oil spills. Because of its elasticity, the absorbed oil can be pressed out for recycling. It is expected to play an important role in the treatment of oil spills at sea. Another part of the performance comes from the fact that the components that make up the aerogel skeleton are at the nanoscale. Some of the properties of the nanoscale particles themselves, in the form of aerogels, tend to be enhanced. For example, the electrode material of lithium batteries-manganese dioxide (MnO2), when it exists in the form of aerogel, the discharge performance of lithium batteries has been greatly improved.

As a kind of material born in the early 20th century, aerogel does not belong to the recently discovered "new material", but its excellent characteristics in all aspects make it widely concerned, and the application of this material still needs to be studied and explored.

Aerogel, silica aerogel, aerogel insulation, aerogel insulation, hydrophobic aerogel

Previous

Next

Previous

Next