NEWS&EVENT

Quality is our core our concept

China develops super-elastic hard carbon aerogel

Release time:

2021-09-02 16:06

Source:

Carbon materials can be roughly divided into graphite carbon, soft carbon and hard carbon according to the difference of carbon atom hybrid orbitals. Soft carbon and hard carbon are mainly used to describe carbon materials prepared by polymer pyrolysis. During the pyrolysis process, some carbon atoms reconstitute into two-dimensional aromatic graphene sheets. If these graphene sheets are roughly parallel, they are easy to be graphitized at high temperatures. This kind of carbon is called soft carbon; if these graphene sheets are randomly stacked and cross-linked by edge carbon atoms, and cannot be graphitized at high temperatures, this kind of carbon is called hard carbon. Generally speaking, graphite carbon and soft carbon have high elasticity, easy deformation, but the strength is low; due to the existence of a large number of sp3-C caused by the hard carbon micro-layer "house of cards" structure, hard carbon materials show great advantages in mechanical strength and structural stability, but the intrinsic nature is brittle and fragile. How to prepare hard carbon materials into super elastic blocks is a challenge.

Recently, inspired by the natural spider web with high strength and elasticity at the same time, a series of hard carbon aerogels with nanofiber network structure were prepared by the template method. This series of aerogels has the advantages of super elasticity, fatigue resistance and good stability.

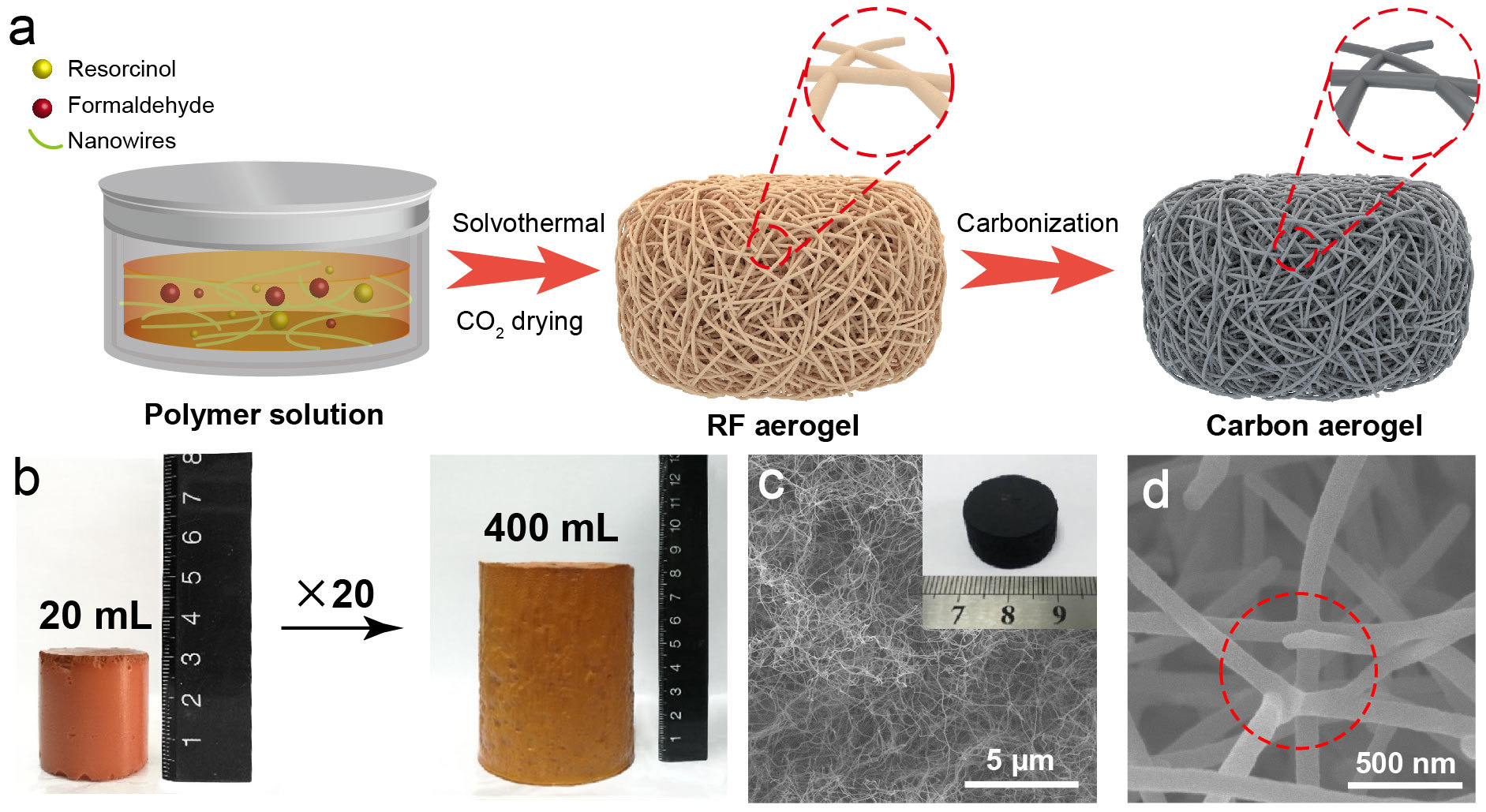

Figure 1. Preparation of hard carbon aerogel. (a) Schematic diagram showing the general synthesis method by using nanowires as templates; (B) Using BCNF @ RF as an example, the macro-synthesis of RF nanofiber hydrogel;(c) SEM image of hard carbon aerogel;(d) showing the nanofiber network structure and fiber-fiber welding points.

By using resorcinol-formaldehyde (RF) resin as a hard carbon source and a variety of one-dimensional nanofibers as structural templates, the researchers prepared RF nanofiber aerogels, and obtained super-elastic hard carbon aerogels through high-temperature carbonization. This hard carbon aerogel has a fine microstructure, consisting of a large number of nanofibers and solders between the nanofibers (Figure 1). This method is simple and efficient, easy to scale up production, by adjusting the amount of template and resin monomer, can easily control the diameter of nanofibers, aerogel density, mechanical properties and so on.

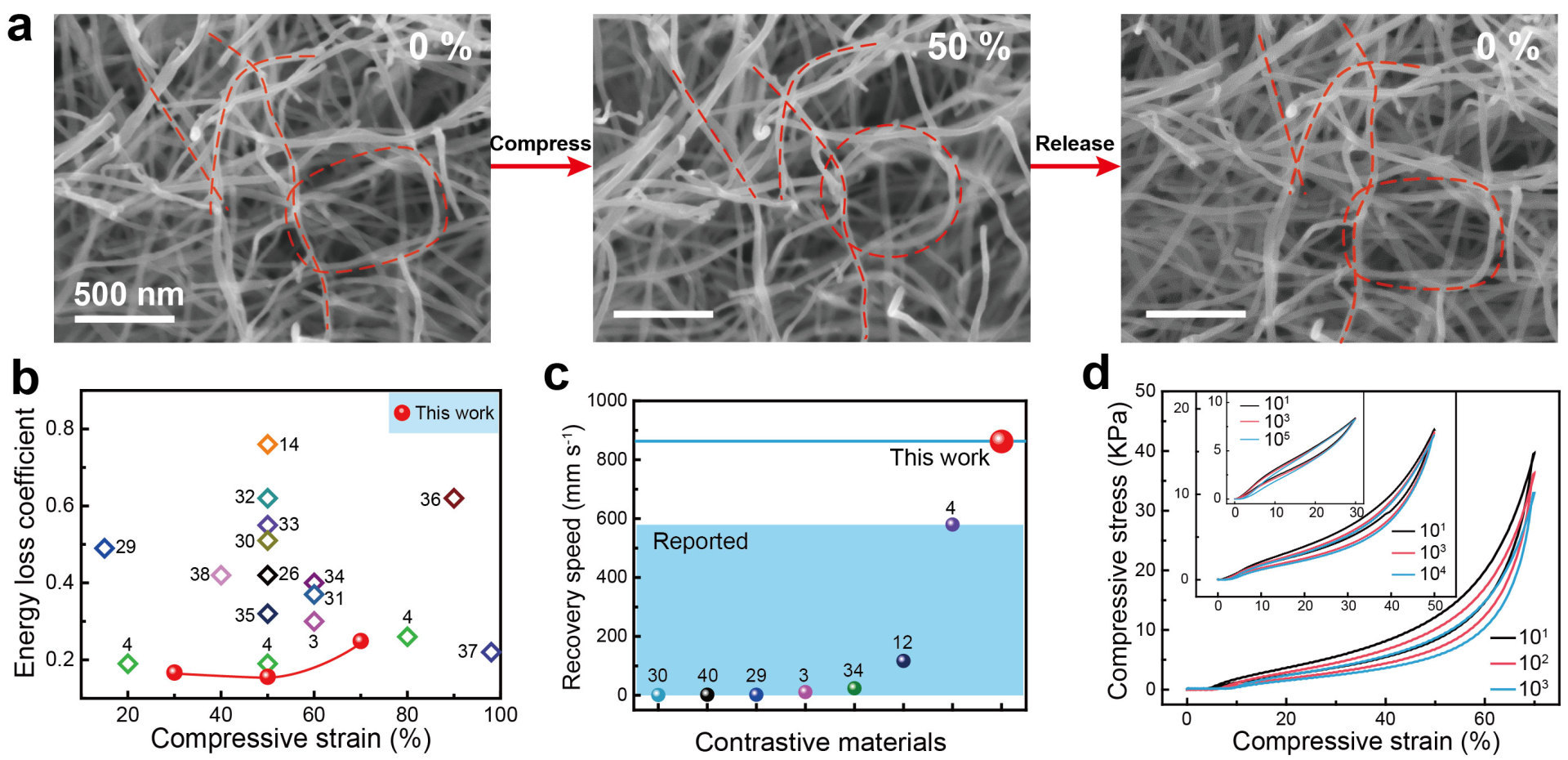

Different from traditional hard and brittle hard carbon blocks, this hard carbon aerogel shows excellent elastic properties (fig. 2), mainly including: structural stability (microstructure can still be recovered after 50% compression); High rebound speed (860mm s-1), higher than many graphite carbon-based elastic materials; Low energy loss coefficient (<0.16), generally, the intermolecular forces existing in graphite and soft carbon materials will cause adhesion and friction, thus dissipating a lot of energy. Fatigue resistance, after 104 cycles of testing at 50% strain, carbon aerogel only shows 2% plastic deformation and maintains 93% initial stress. The researchers also explored the application of this hard carbon aerogel in elastic conductors. After multiple compression cycles at 50% strain, the resistance is almost unchanged, showing stable mechanical-electrical properties, while maintaining superelasticity and resistance stability under harsh conditions (such as in liquid nitrogen).

Figure 2. Mechanical properties of carbon aerogels. (a) In-situ SEM of BCNF @ C aerogels; (B) Comparison of energy loss coefficients of different materials;(c) Comparison of rebound velocities of different materials;(d) Stress-strain curves of carbon aerogels under different cycles

Based on its excellent mechanical properties, this hard carbon aerogel is expected to be used in stress sensors with high stability, large range (50 KPa), stretchable or bendable. In addition, this method can be extended to prepare other non-carbon-based composite nanofiber aerogels, providing a new way to transform rigid materials into elastic or flexible materials by designing the microstructure of nanofibers.

Aerogel, carbon aerogel, super elastic hard carbon aerogel, hard carbon aerogel