NEWS&EVENT

Quality is our core our concept

Silicon dioxide: the "universal pharmaceutical excipient" for pharmaceutical preparations

Release time:

2025-05-20 14:31

Source:

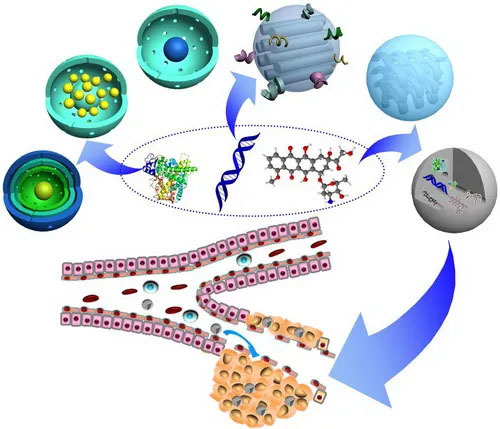

Medicine has been closely related to people's lives since ancient times. The production of drugs began with traditional medicine and later evolved to separate and extract natural medicines from natural substances, gradually developing and establishing an industrial production system for chemical drugs. Medicinal excipients play a crucial role in the pharmaceutical industry. Medicinal excipients refer to the excipients and additives used in the production and formulation of drugs. In addition to shaping, acting as carriers, and improving stability, they also have important functions such as solubilization, solubilization assistance, and sustained and controlled release. They are important components that may affect the quality, safety, and effectiveness of drugs. Silicon dioxide, as a widely used inorganic material, is also a very useful pharmaceutical excipient in the pharmaceutical field. The structural formula of auxiliary silica is mSiO2 · nH2O, which is a white powder with good fluidity, high purity, and no pollution. It has the characteristics of small particle size, large specific surface area, and many pores. At the same time, the silicon hydroxyl groups distributed on the surface make it have good adsorption performance. Adding medicinal excipient silica can effectively improve the quality and performance of drug formulations, especially tablets, greatly enhancing the market competitiveness of drugs. Its application in drug formulations has received increasing attention.

01.Used for lubricants

Silicon dioxide, a medicinal excipient, can be used as a lubricant in many capsules, dispersible tablets, and other drugs. It can prevent the adhesion of microspheres, accelerate the dissolution rate of dispersible tablets in water, have good dispersion uniformity, and controllable quality.

02.Used as a flow aid

In order to ensure smooth feeding and dispensing of pharmaceutical tablets, as well as reduce viscosity and friction between particles and between tablets and the mold wall, and to make the surface smooth and beautiful, a certain amount of flow aid is added. The wet granulation and tablet pressing process is the most widely used tablet pressing process, suitable for relatively stable drugs. Due to the difficulty of most drugs simultaneously possessing good fluidity, compressibility, and the required release characteristics for tablets. Therefore, by wet granulation and adding other flow aids, the preparation requirements of different materials and tablets can be met.

The tablets prepared by adding medicinal excipient silica as a flow aid have good molding and taste.

03.Used for anti adhesive agents

When medical silicon dioxide is applied to gel plaster, gel plaster can have the advantages of large drug loading, good transdermal effect, good skin compatibility and non irritation. This dosage form is recognized as a new direction of development of transdermal drug delivery system and a new type of preparation with great potential.

04.Used for adsorbents

The use of pharmaceutical excipient silica as an adsorbent material in solid formulations can greatly improve the in vitro dissolution rate and solve the problem of low bioavailability of traditional drugs.

05.Used for anti-static agents

Powder electrostatic adsorption often occurs during the preparation of particles in fluidized beds, and it is necessary to add anti-static agents to eliminate powder electrostatic adsorption. The surface of medicinal excipient silica contains a large number of hydrophilic groups, which absorb moisture from the air on the surface of the powder coating to form an electrophilic film or reduce surface resistance through proton transfer, thereby exerting anti-static effects.

The Application of Silicon Dioxide in the New Field of Pharmaceutical Preparations

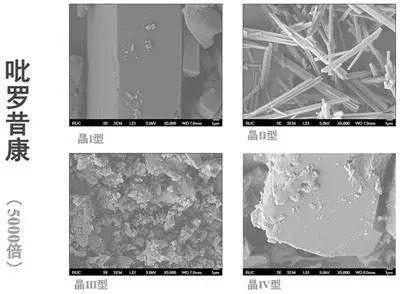

01.Used as a crystal stability promoter

Due to the different states of crystalline drug substances, there can also be significant differences in their crystal stability. As a drug crystal substance, it must possess certain stability properties, which is the most basic requirement for ensuring drug quality. The stability of drug crystal form refers to the stability of the crystal form itself, that is, the ability to maintain the stability of the crystal form substance state under different environmental conditions; In addition, since drugs exist in dosage form, it is also necessary to ensure the stability of advantageous drug crystal forms and various pharmaceutical excipients in the clinical application process of drug formulations.

As research has found, after being treated with amorphous excipients such as silica, some drugs such as clopidogrel bisulfate raw materials have better crystal stability and drug compatibility.

02.Used for grinding aids

The modification of medicinal excipient silica in dispersed tablets significantly enhances the water absorption capacity of extracted drugs, greatly reducing the disintegration time. Moreover, co grinding of medicinal excipient silica and raw materials can enhance the disintegration effect of dispersed tablets. This is because the medicinal excipient silica, as a grinding aid, can promote the pulverization and refinement of raw materials, providing a high porosity structure for rapid water infiltration.

03.Used for colon targeted preparations

In recent years, studies have shown that colon targeted drug delivery systems have advantages such as low dosage, high efficacy, low side effects, and convenient administration. This formulation can prevent drugs from being destroyed or inactivated when passing through the gastrointestinal tract, and immediately disintegrate and release them upon reaching the ileocecal site of the human body, thereby exerting therapeutic effects. Pharmaceutical excipient silica, as a new type of pharmaceutical excipient, has begun to be applied in this drug formulation. Mesoporous silica has the advantages of being able to load a large amount of insoluble drugs and provide mechanical stability to the lipid layer.

04.Used for sustained-release formulations

A sustained-release formulation refers to a preparation that slowly and non steadily releases a drug in a prescribed release medium after oral administration. Compared with the corresponding regular formulation, the frequency of administration is reduced, and it can significantly increase patient compliance or reduce drug side effects. Pharmaceutical excipient silica can not only increase the rate of lipolysis, promote drug absorption, but also delay the in vitro release of some drugs.

05.Other areas

At present, there are also pharmaceutical excipient silica modified products in the pharmaceutical field, including two categories: self structural modification and blending modification. If the medicinal excipient silica is prepared into mesoporous silica nanoparticles, it can have a tailored pore structure and ultra-high surface activity, and can be used as an effective therapeutic drug delivery carrier, with significant advantages in drug packaging and transportation.

After microcrystalline cellulose and medical auxiliary silicon dioxide are mixed in a proper proportion, a new medical auxiliary material, namely silicified microcrystalline cellulose, is prepared by spray drying. This auxiliary material has good fluidity, compressibility, moisture absorption resistance, high disintegration and other unique properties, so it can be used as a functional diluent for direct compression tablets, solve the problem of uneven distribution of active ingredients in tablets, and meet the preparation requirements of tablet cores, orally disintegrating tablets, and dispersible tablets.

In addition, due to the strong adsorption, hydrophilicity, biocompatibility, and surface multi hydroxyl properties of nano silica, it can be used as a carrier to prepare high-performance biosensors, biomarkers, and detection materials through modification methods.

conclusion

The continuous improvement of drug safety and efficacy, as well as the full implementation of consistency evaluation between generic drugs and original drugs, have put forward higher requirements for the quality of pharmaceutical excipient silica. The future development trend is to modify the pharmaceutical excipient silica to obtain better performance.

At present, some new research directions and technologies are not yet mature, such as the study of mesoporous silica nanoparticles in the medical field, which mostly focuses on cell experiments, with relatively few animal experiments and no clinical trials involved. The innovative development of silica in the pharmaceutical field still requires joint efforts from the materials industry and medical research.

silicon dioxide,silica,medicine additive