NEWS&EVENT

Quality is our core our concept

What are the application advantages of aerogel thermal insulation materials?

Release time:

2025-06-21 17:05

Source:

In the field of petrochemicals, the part of the steam transmission system with a higher heat loss rate is the steam transmission pipeline, and the heat loss generated can account for about 25% of the total heat loss. Improving the insulation effect of the steam transmission system pipeline is an important way to reduce the overall heat loss of the system. As one of the new thermal insulation materials, aerogel thermal insulation material has good thermal insulation performance, strong compression resistance, long service life and other advantages. Therefore, we can try to use aerogel insulation materials to transform the pipeline of the steam transmission system, so as to enhance the insulation performance of the pipeline and reduce the energy loss caused by heat loss. In this paper, the case analysis method is used to discuss the thermal insulation effect of aerogel used for steam transmission pipeline in an oil field. Elaborate on testing methods, evaluation indicators, and measurement point layout, carry out insulation material selection and structural optimization design, and calculate the thickness of different insulation structures. The results show that the thermal insulation performance of aerogel composite thermal insulation structure is significantly better than that of composite silicate felt structure, double composite silicate tile and composite silicate felt combined thermal insulation structure, which confirms the application advantages of this material in steam transmission system.

Project overview

A total of 826.1km of steam transmission pipelines have been completed in an oil field. The pipelines in different areas use single-layer tile, nano aerogel, composite silicate felt, and double-layer silicate tile as thermal insulation pipelines, with the lengths of 44.5km, 75.4km, 16km, and 690.2km respectively. These thermal insulation materials are in place. The application of aerogel thermal insulation materials is still in the trial stage, and the external use of steel materials as fixed piers, combined with the use of sliding thermal insulation piers, takes a long time to construct and does not have a good operating environment. At present, among the four types of insulation materials for pipelines, double-layer silicate tiles have the best insulation effect. However, after long-term use, due to high temperature, compression or vibration, and excessive thermal conductivity, there have been problems such as excessive heat loss and cracking of pipeline joints. Aerogel is a porous solid material with only a few nanometers of pores. The main component of this material is silicon dioxide, which is less polluting, highly flexible, and has a relatively low thermal conductivity. At normal temperature, the thermal conductivity is only 0.017W/(m · k) at the lowest. It also has good flame resistance or flame retardancy, and can be used in high and low temperature environments. Therefore, this paper attempts to transform the thermal insulation structure of the steam transmission system into an aerogel composite thermal insulation structure in order to improve the thermal insulation performance of the steam transmission pipeline.

Thermal insulation effect test of aerogel material in steam transmission system

Thermal insulation effect testing method

In order to determine the application effect of aerogel insulation material in steam transmission system, two methods were used to test the heat loss of steam transmission pipeline. The first method is the heat flux meter method, which is based on the theory of "one-dimensional line heat" and believes that the heat transfer process in the measured area is extremely similar to the one-dimensional unsteady heat conduction process of the internal heat source type. Therefore, the thermal conductivity of the measured material can be determined based on its thermal conductivity, internal heat source strength, density, and specific volume. This method is not easily affected by external factors and the operation process is simple. During the detection process, the heat flux sensor needs to be installed on the surface of the object being measured or inside its insulation structure. Based on close contact between both parties, the heat flux density, wind speed, pipeline surface temperature, and ambient temperature are tested to determine the heat loss of the pipeline.

The second method is the surface temperature method, which is mainly used to measure the surface temperature of exposed pipelines, valves, and pipe supports. Based on the size and wind speed of the measured object, combined with the measured environmental temperature and surface temperature, the heat loss of the pipeline can be solved.

Evaluation indicators for insulation effect

When evaluating the heat loss of a steam pipeline, there are two evaluation indicators: the outer surface temperature of the measured object and the heat loss generated by the steam pipeline under year-round operating conditions.

Set up measuring points

When testing the insulation effect of the steam transmission system pipeline, 4 and 3 test sections should be selected on the straight pipe section and elbow respectively, and a measuring point should be set at each section circumference, with an interval of 20m and marked. At the same time, the environmental temperature detection point and the wind speed detection point are respectively set at a distance of 1 meter from the pipeline. Using a thermal imager as a tool to capture thermal images of pipeline locations for analyzing the insulation performance of steam pipeline insulation structures.

Optimization scheme for insulation structure of steam transmission pipeline

When optimizing the insulation structure design of steam transmission pipelines, suitable insulation materials should be selected and the insulation structure should be designed reasonably. Nano aerogel felt and composite silicate felt are preferred as thermal insulation materials, both of which have the advantages of low coefficient and good thermal insulation performance. From the perspective of thermal insulation structure, two optimization design schemes of thermal insulation structure can be designed. The first scheme is to use aerogel thermal insulation felt as the main body and composite silicate felt as the auxiliary to enhance the tightness of the thermal insulation structure, and then set aluminum foil on the inside of the thermal insulation structure, use the good reflection function of this material to reduce the heat transfer of heat radiation, and then wrap galvanized iron sheet on the outside of the entire insulation layer to strengthen the protection function; The second solution is to use no aerogel material, directly use composite silicate felt to build the insulation layer, and then wrap the galvanized iron sheet on the outside of the insulation layer. To prevent high heat transfer between pipelines and supports, two types of insulation supports, fixed and movable, need to be used to enhance the insulation performance of the steam transmission pipeline.

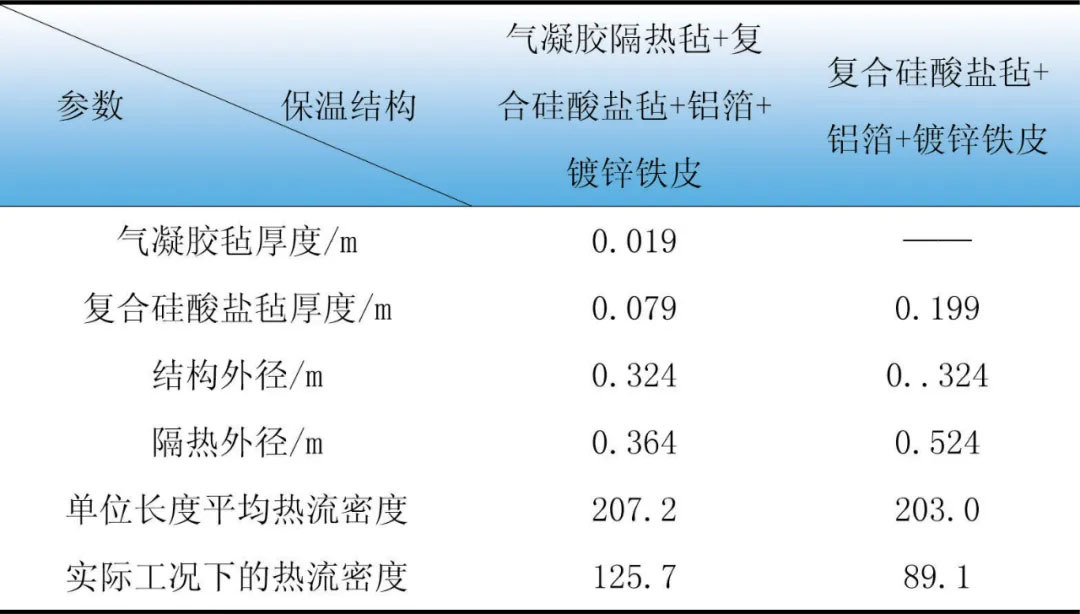

The insulation performance of steam transmission pipelines is affected by three factors: thermal conductivity, thermal convection, and thermal radiation of the pipelines. To simplify the analysis process, the influence of pipeline radiation and steam flow velocity is not considered in this calculation. Only two factors, heat convection and heat conduction, are taken into account. The insulation process is regarded as the steady-state heat transfer process of a circular tube without an internal heat source composed of different materials, and the unit length heat flux density of the bare tube and the external insulated material pipeline are calculated separately. Taking the D325 steam pipeline as an example, calculate the thickness of the insulation structure. The superheated steam pressure of the medium inside this tube is 13.5 MPa, the temperature of the medium inside the tube and the external environment are 350 ℃ and 8.4 ℃ respectively, and the wind speed is 1m/s. The thermal conductivity of aerogel, composite silicate and steel pipe used for pipe insulation structure is 0.026, 0.082 and 43.2 respectively, and the unit is W/(m · k). Assuming that the heat loss of the steam transmission pipeline is consistent, and the external surface temperature of the insulation structure does not exceed 50 ℃, under this condition, the thickness of two different forms of insulation structures, aerogel and composite silicate, are calculated. See Table 1 for the calculation results.

Table 1 Thickness of Different Insulation Structures

Test results and analysis of thermal insulation effect of aerogel

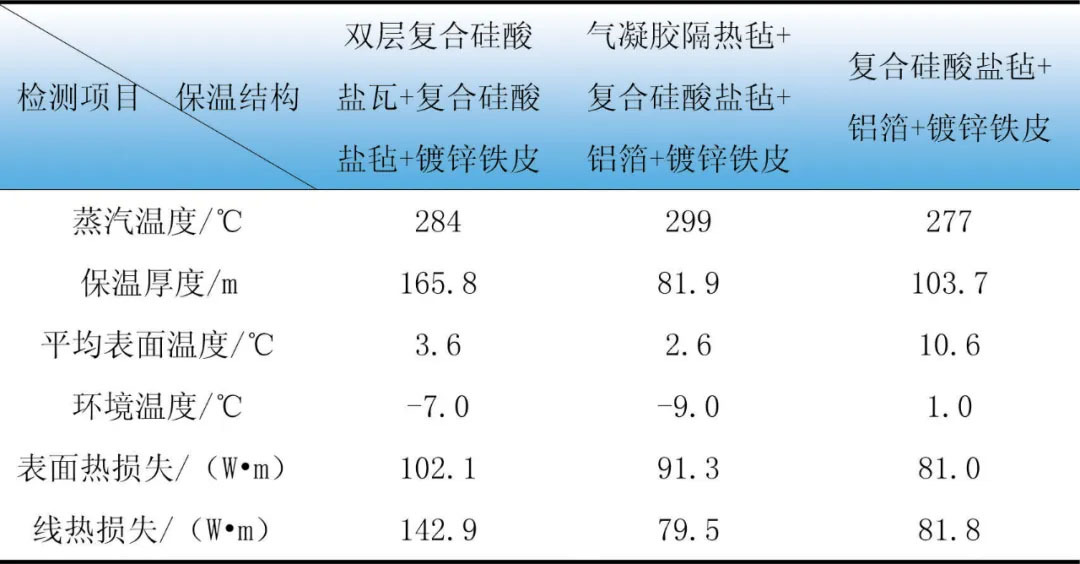

The original insulation structure used for the steam pipeline network in this project was double-layer composite silicate tiles and composite silicate felt for the insulation materials of the straight pipe section and the elbow section, respectively. The protective layer was made of galvanized iron sheet, and no insulation measures were taken for the pipe support brackets. A total of 309 sections were obtained on each pipeline, with intervals of 20m between each section. Four measuring points were set up on each section, and 941 measuring points were selected for other structures such as valves and pipe supports. Then, the surface temperature, ambient temperature, and wind speed values of the pipeline were detected separately, and the heat flux density of the pipeline was calculated. A total of 7450 raw data were obtained. Based on these data, analyze the heat loss of various pipe sections, pipe supports, valves, and other structures of the steam transmission pipeline under year-round operating conditions. Then, using the two different insulation structure optimization schemes proposed above, some pipelines of the steam transmission system were modified, and the insulation effect of the modified steam transmission pipelines was closely monitored. The insulation performance test data of the steam transmission pipeline before and after the renovation are shown in Table 2.

Table 2 Thermal insulation performance test results of different insulation structures before and after renovation

Result analysis

According to the data shown in Table 2, it is found that the surface heat loss and linear heat loss of the two types of insulation structures after modification have decreased compared with those before modification. However, compared with the two types of insulation structures, the surface heat loss and linear heat loss of the composite insulation structure of aerogel+composite silicate felt and the composite silicate felt insulation structure are not significantly different. However, the ambient temperature of the two types of insulation structures when tested is -9 ℃ and 1.0 ℃ respectively, and the average surface temperature is 81.9 ℃ and 103.7 ℃ respectively, and the insulation thickness of the latter is 21.8m more than the former. This shows that the thermal insulation performance of the former is superior. When comparing the double layer composite silicate tile+composite silicate felt insulation structure before the transformation with the modified aerogel gel insulation felt+composite silicate felt structure, it is found that the average surface temperature of the two is 3.6 ℃ and 2.6 ℃ respectively when the ambient temperature is -7 ℃ and -9 ℃. Although the temperature difference is not significant, the insulation thickness of the former is about twice that of the latter. The surface heat loss and linear heat loss obtained after the detection are both lower than the latter, which indicates that the thermal insulation performance of the aerogel composite insulation structure is better.

The infrared detection method was used to detect the double-layer silicate tile insulation layer and aerogel composite insulation layer before and after the transformation. It was found that the insulation material was damaged in some parts of the straight pipe section of the former. At the same time, the temperature at the insulation tile joint was much higher than the normal value, and there was obvious heat leakage; At the location where the elbow and straight pipe are connected, there is also a phenomenon of high temperature, indicating that this is also a heat leakage location, which will result in high heat loss. However, infrared ray detection of aerogel composite insulation structure found that no leakage hot spots were found in all parts of the pipe section during the whole operation period, indicating that its sealing performance is better, the insulation performance is more ideal, and it is more suitable for use as insulation material for steam transmission system.

The steam transmission pipeline will generate certain heat loss, and the main reason for this problem is improper selection of insulation materials and unreasonable setting of insulation structures. Combined with practical examples, this paper proposes a composite insulation structure with aerogel as the main material, composite silicate felt as the auxiliary material, and aluminum foil and galvanized iron sheet as the inner layer and outer wrapping layer respectively. Through thermal insulation performance test, it is found that the thermal insulation effect of this structure is better than that of the composite silicate structure alone, combined with the double-layer composite silicate tile and composite silicate felt structure, and there is no leakage hot spot, indicating that aerogel thermal insulation material has high application value in the steam transmission system.

aerogel,aerogel thermal insulation,thermal insulation material

Previous