NEWS&EVENT

Quality is our core our concept

Super elastic fireproof aerogel with hierarchical structure, prepared by double template assisted microbubble engineering

Release time:

2025-06-30 21:40

Source:

Super elastic aerogel has significant advantages in advanced thermal management system of energy-saving buildings due to its ultra-low thermal conductivity. However, inorganic aerogels have the problems of brittleness and poor processability, while organic aerogels face the challenges of high manufacturing costs and insufficient elastic recovery. In this study, a dual template (ice and bubble) strategy was used to prepare an ultra light, super elastic aerogel inspired by the stress dissipation dome structure, which has a hierarchical pore structure. By improving the Tessari method, engineering microbubbles to form macroscopic pores (≈ 100 µ m) was achieved, while the ice template introduced aligned pores with a size of several micrometers during the freeze-drying process. The synergy between rigid collagen (Ge) skeleton, flexible polyvinyl alcohol (PVA) node and potassium salt enhanced crystal domain endows the aerogel with excellent elasticity, ultra-low density and thermal conductivity. The flame retardant performance is achieved through potassium salt mediated catalytic carbonization, reducing the peak heat release rate by 54% and endowing it with self extinguishing behavior. The introduction of microbubbles in the precursor can provide macro pores for the aerogel. These pores disperse the internal stress during the deformation of the aerogel, and the dynamic hydrogen bond endows it with rapid water assisted self-healing ability and closed-loop recoverability. The use of commercial compressed air foaming systems for scalable production with low raw material costs further highlights its industrial feasibility. Combined with biodegradability and excellent thermal insulation performance, this study has opened up a new direction of sustainable, fire safe aerogels for multifunctional applications. Aerogels have shown a wide range of applications in sensing, thermal insulation and flame retardants due to their unique characteristics such as low density, high porosity and excellent thermal insulation. Although classical inorganic silica aerogels have been commercialized on a large scale, their practical applications are fundamentally limited by the inherent brittleness of silica networks. In addition, the precursors used to produce silica aerogels are derived from petroleum, which raises environmental concerns about sustainability. Organic polymer aerogels, including polyimide and syndiotactic polystyrene aerogels, have become candidate materials for thermal insulation textiles. However, these materials are plagued by dependence on non renewable resources and high manufacturing costs. In contrast, renewable biomass derived gel based on nano cellulose and protein have been developed for thermal management applications. Nevertheless, the industrial application of nano cellulose aerogels still faces two challenges: i) the energy intensive extraction process involving chemical treatment (such as TEMPO mediated oxidation) has led to a significant increase in raw material costs (30-100 US dollars/kg 11); Ii) Due to irreversible hydrogen bonding between adjacent cellulose nanofibers under compressive stress, most nanocellulose structures exhibit insufficient elastic recovery (permanent collapse after cyclic compression deformation exceeding 30%). This kind of mechanical defect is especially harmful in the application of aerogels, because the lack of resilience will lead to the flattening of the structure under load, and eventually lead to the collapse of pores, which will lead to the decline of thermal insulation performance.

PREPARATION

1. Preparation of biomass gas gel First, prepare 10 wt.% Ge solution and 4 wt.% PVA solution respectively. Then, the Ge solution was mixed with PVA solution in a mass ratio of 1:2 to obtain a Ge/PVA solution. Add a specific amount of APG (1 wt.%) and potassium formate (2 wt.%) to the Ge/PVA solution while stirring to obtain a Ge/PVA/APG/potassium formate solution. In order to investigate the effect of the ratio of PVA to Ge on the performance of aerogels, solutions with different ratios of PVA to Ge were also prepared. Using an improved Tessari method to create bubble templates. This improved technology uses two syringes connected by flexible tubes: one 30 mL medical syringe (Hongda Company) containing Ge/PVA/APG/potassium formate solution, and the other containing air. The high shear rate required for effective gas-liquid mixing is achieved through multiple reciprocating cycles (push-pull motion) between syringes. The solution air mixture at the outlet of the syringe spontaneously "explodes" and breaks into microbubbles. By adjusting ER (=gas volume/liquid volume), the template density can be precisely adjusted. Tessari method is convenient for us to study the influence of ER on the performance of aerogels under the condition of constant bubble size in the laboratory. We use a syringe to transfer the obtained foam template to a silicone mold, and then freeze it in a refrigerator at -20 ° C for 5 hours to form an ice template. Use a lyophilizer to freeze dry the frozen sample for 48 hours to obtain the final super elastic aerogel sample.

MAIN CONCLUSIONS

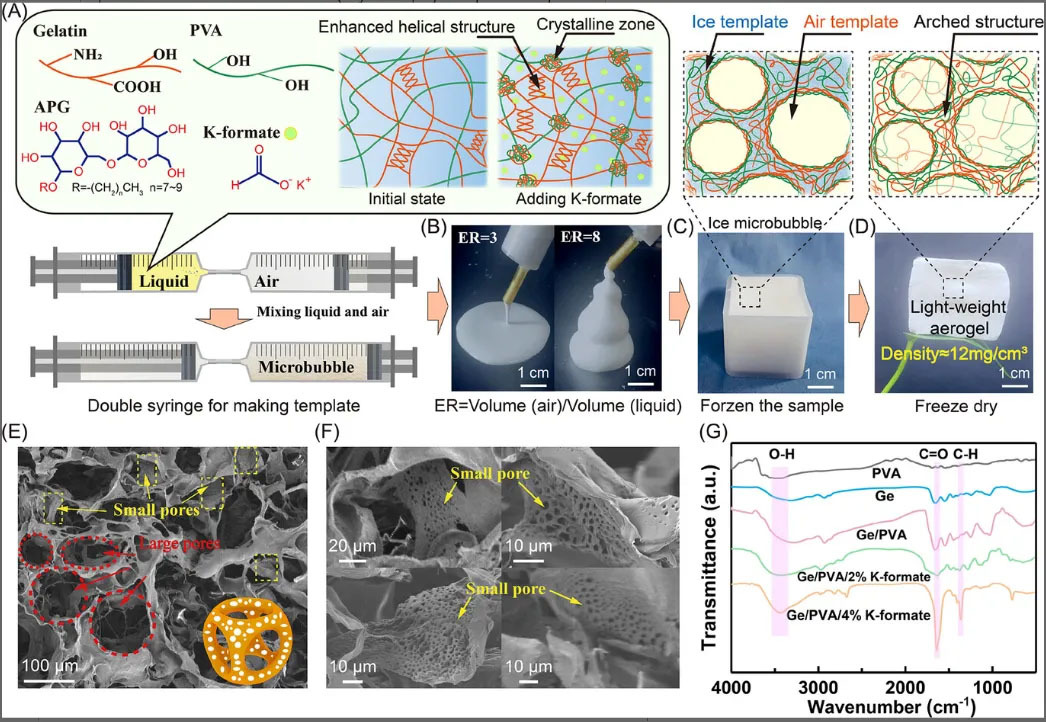

Figure 1, A) Large pore mechanism formed by dual syringe foaming method, in which economically efficient Ge and PVA serve as structural frameworks, while flame-retardant potassium salt induces crystal domain formation to achieve mechanical regulation. B) By adjusting the volume fraction of gas in the syringe, the adjustable density and rheological properties of the bubble template can be achieved. C) An ice template containing bubbles for forming aerogels. D) Ultra light aerogel supported by blades (ER=8). E. F) SEM images show the macroporous structure (≈ 100 µ m) and several µ m sized pores in the aerogel. G) FTIR spectra of various aerogels. Unless otherwise specified, the ratio of Ge to PVA in aerogel samples is 1:2

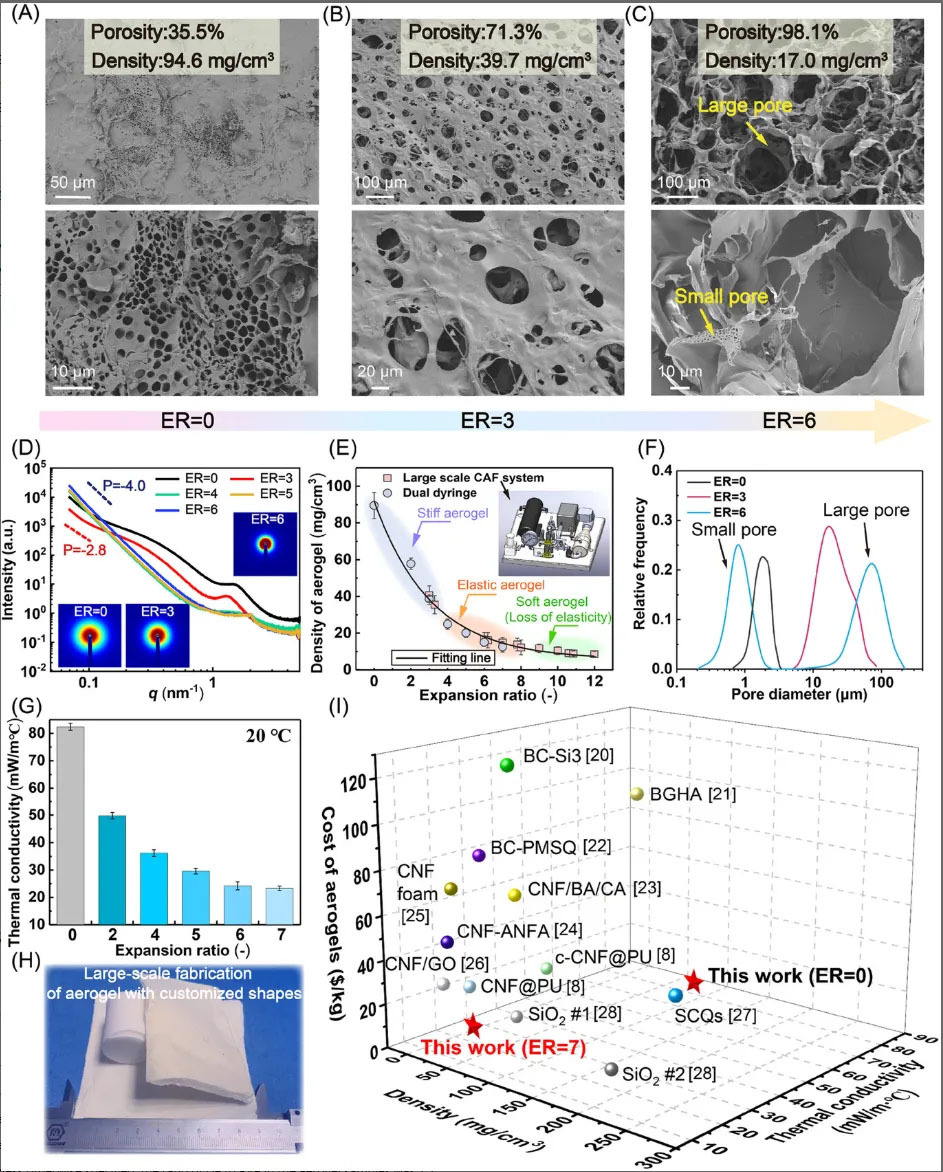

Fig. 2. A – C) SEM images of aerogels with different ER values. D) Small angle X-ray scattering (SAXS) profile of porous gas gel. E) The density of aerogels produced by the double syringe method and customized large-scale compressed air foam system was compared. F) Pore size distribution of aerogels with different ER values. G) Thermal conductivity of different ER aerogels. H) A compressed air foam system was used to scale up the preparation process of porous air gel. I) Comprehensively compare the thermal conductivity, density and raw material cost of the aerogel developed in this study with that of the aerogel reported previously. 8-28 Unless otherwise specified, the ratio of Ge to PVA in aerogel samples is 1:2

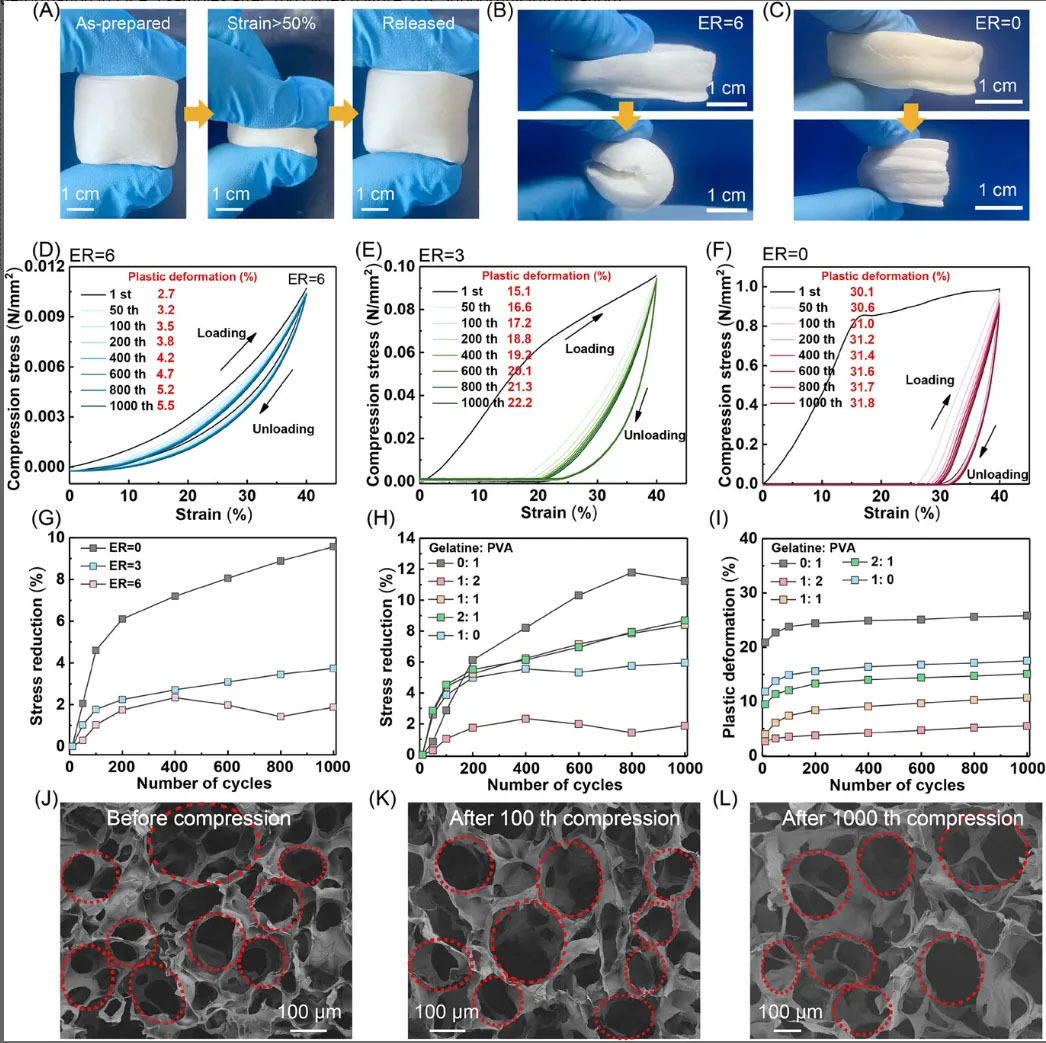

Fig. 3. A) Compression resilience of Ge/PVA/APG (Ge: PVA=1:2) aerogel at ER=6. B. C) Comparative photos of Ge/PVA/APG aerogels with ER=6 and ER=0 before and after folding. D – F) Compressive stress-strain curve of aerogel samples under different ER conditions (1000 cycles under 40% strain). G) The stress of Ge/PVA/APG aerogels decreased during cyclic compression testing under different ER values. H. The effect of Ge PVA ratio on stress reduction and plastic deformation during 1000 compression tests (ER=6). J – L) SEM image of pore structure evolution in Ge/PVA/APG aerogel after 100 and 1000 compression cycles. Unless otherwise specified, the ratio of Ge to PVA in aerogel samples is 1:2

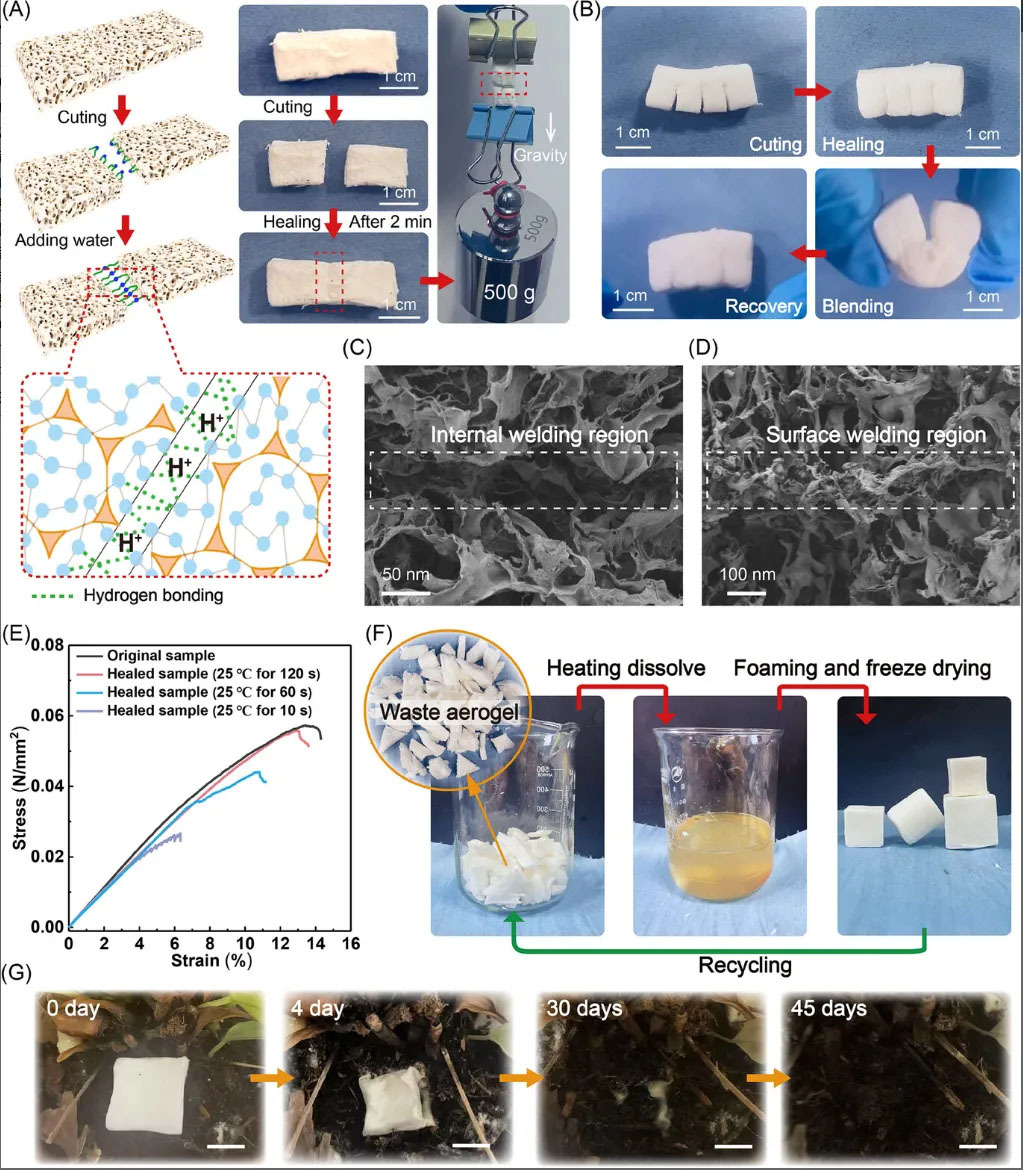

Fig. 4, A) Self repair ability of superelastic Ge/PVA/APG aerogel through dynamic hydrogen bond interaction. The repaired aerogel can withstand a tensile load of 6000 times its own weight. B) The Ge/PVA/APG aerogel with multi segment fracture shows elastic recovery during bending deformation after self repair. C. D) SEM images of internal and external welding interfaces of self-healing Ge/PVA/APG aerogel. E) Tensile stress-strain curves of Ge/PVA/APG aerogels after different repair times. F) Schematic diagram of closed loop recovery scheme for Ge/PVA/APG aerogel samples. G) Biodegradation process of Ge/PVA/APG aerogel samples in the soil environment (the scale represents 12.5 mm). Unless otherwise specified, the ratio of Ge to PVA in aerogel samples is 1:2

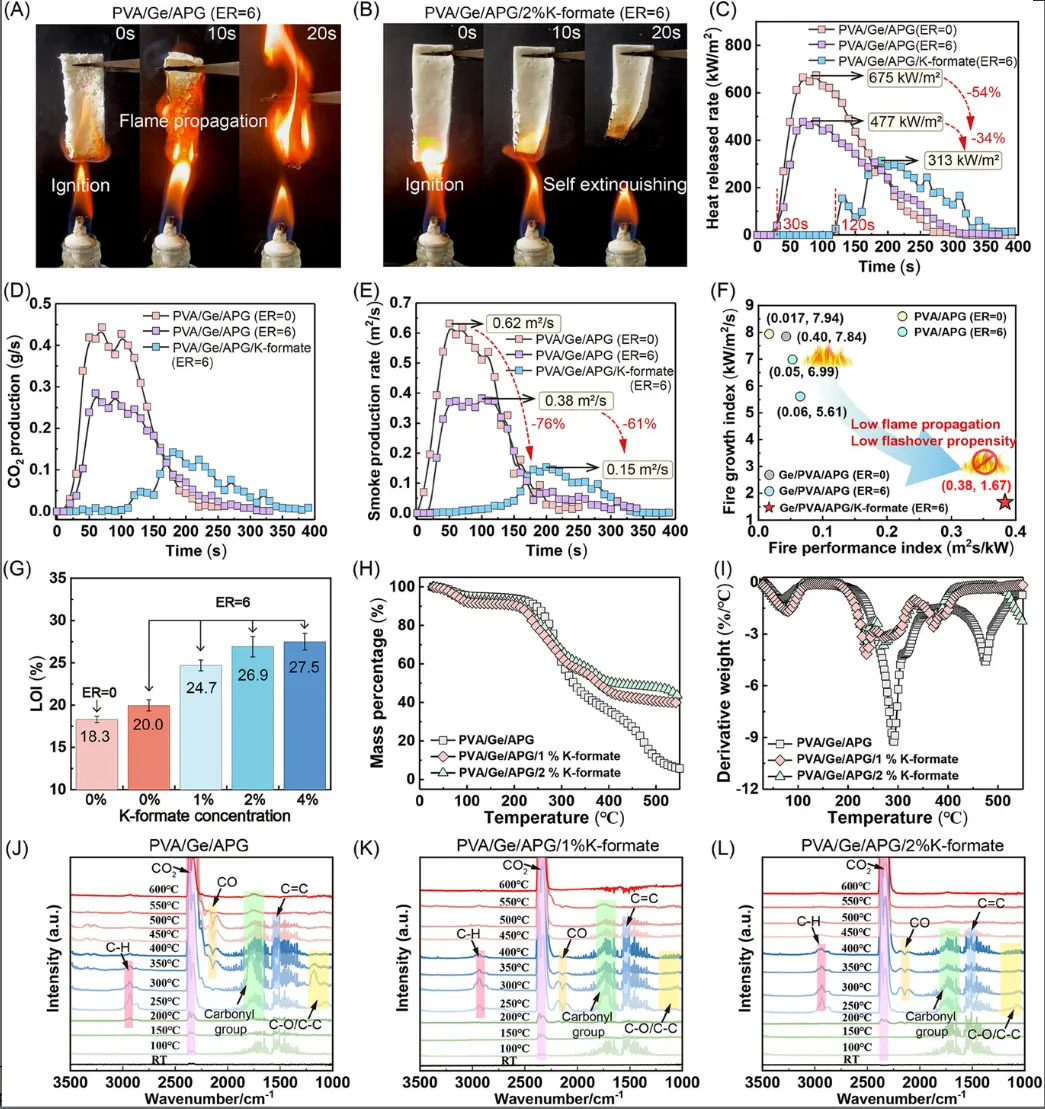

Fig. 5, A, B) Flammability test of Ge/PVA/APG aerogel with and without potassium formate (ER=6). CE) Heat release rate, CO 2 generation rate and smoke generation rate of aerogel samples when burning under 35 kW m − 2 radiant heat flux. F) FGI and FPI of aerogel samples. G) LOI of aerogel samples. H. I) TG and DTG curves of aerogel samples. J-L) FTIR spectra of pyrolysis products of aerogel samples. Unless otherwise specified, the ratio of Ge to PVA in aerogel samples is 1:2

CONCLUSION

In this study, a dual template strategy (ice template and bubble template) was used to prepare ultra light and super elastic bio gas gel with hierarchical structure. By synergistically integrating Ge, PVA, APG and K-formate, the aerogel achieved excellent mechanical elasticity (residual strain of 5.5% after 1000 compression cycles at 40% strain), ultra-low density (12 mg cm − 3) and excellent thermal insulation performance (24 mW/(m ° C)). Effective stress dissipation can be achieved through local deformation through microbubble blockage and ice template design of large pores (≈ 100 µ m) and small pores several µ m in size. We found that the elastic behavior of aerogels was due to the blocking state of bubbles in the foam template. A larger ER will result in complete loss of elasticity, while a smaller ER will result in excessive rigidity. The optimum elasticity of aerogel is observed in the range of ER 4 – 8, which is slightly larger than the critical ER ≈ 2.78 required for bubble blocking transformation in 3D foam template. Due to the existence of dynamic hydrogen bond network, the aerogel shows excellent self-healing ability (strength recovery of 90% within 2 minutes) and closed-loop recoverability through water assisted reprocessing (efficiency ≈ 100%). In addition, potassium salt modification endows it with inherent flame retardancy by catalyzing the formation of carbon and establishing a thermal oxygen barrier (LOI=27.5%, reducing smoke generation rate by 76%). We also highlighted the potential applications of superelastic aerogels in smoke capture and radiation cooling. This aerogel is cost-effective (5.24 US dollars/kg), scalable and fully biodegradable. Its comprehensive performance is better than that of traditional cellulose based aerogels (30-100 US dollars/kg), providing potential for change in sustainable thermal insulation, fireproof materials and energy-saving technologies.

aerogel,thermal insulation materials

Previous