NEWS&EVENT

Quality is our core our concept

Flame retardant black technology: aerogel thermal insulation materials create a "firewall" for electric vehicle batteries

Release time:

2024-11-02 00:00

Source:

With more and more electric vehicles on the road, although battery fires are relatively rare, their potential dangers have attracted increasing attention. Compared to gasoline powered vehicles, battery fires are more difficult to extinguish and pose a higher risk of reignition, posing a serious threat to drivers and rescue personnel. Thermal barrier materials can be placed inside electric vehicle batteries to prevent or slow down the diffusion of heat and flames within the battery pack. Thermal barrier materials can significantly enhance the safety of batteries. Automakers such as General Motors, Toyota, and Audi have already used this material in their vehicles.

When lithium-ion batteries are damaged or short circuited, the phenomenon of "thermal runaway" may occur, which is a feedback loop of heat and chemical reactions that may lead to fire or explosion. The battery pack of an electric vehicle is composed of multiple small battery units, so once a unit has a problem, it may affect the entire battery pack.

Thermal barrier materials can be placed between battery cells to form a barrier, preventing problems from spreading. According to the design scheme of the automobile manufacturer, the aerogel material can at least slow down the propagation speed of the heat runaway, and win enough escape time for the driver. Alternatively, car manufacturers can use these materials to design battery packs that can locally isolate faults, thereby avoiding vehicle fires and limiting damage to a small area.

Because the main component of aerogel is tiny air bag, it has excellent heat insulation effect. As early as the early 2000s, research funding was provided to explore its applications in fields such as spacesuits. Afterwards, materials will be provided to facilities such as oil refineries and liquefied natural gas terminals.

Although aerogels can reduce the severity of battery fires, they cannot completely prevent thermal runaway events. At present, there is no commercial technology that can reliably prevent thermal runaway events. A recent study on lithium-ion battery safety equipment has just been released. Lithium ion batteries contain flammable materials inside and store a large amount of energy.

Automakers and battery manufacturers have taken some measures to reduce the risk of thermal runaway, including battery management systems that can monitor and control battery conditions to prevent fires from occurring. Thermal insulation materials, especially materials made of aerogel, are one of the effective tools to limit the damage caused by thermal runaway events.

However, a potential drawback of such materials is that they can increase the volume of the battery, thereby reducing its energy density - the amount of energy stored per unit volume or weight. Higher energy density means longer range, which is a key concern for many electric vehicle consumers. The advantage of aerogel is that it is very light and mainly composed of air, so its influence on energy density is less than that of other materials.

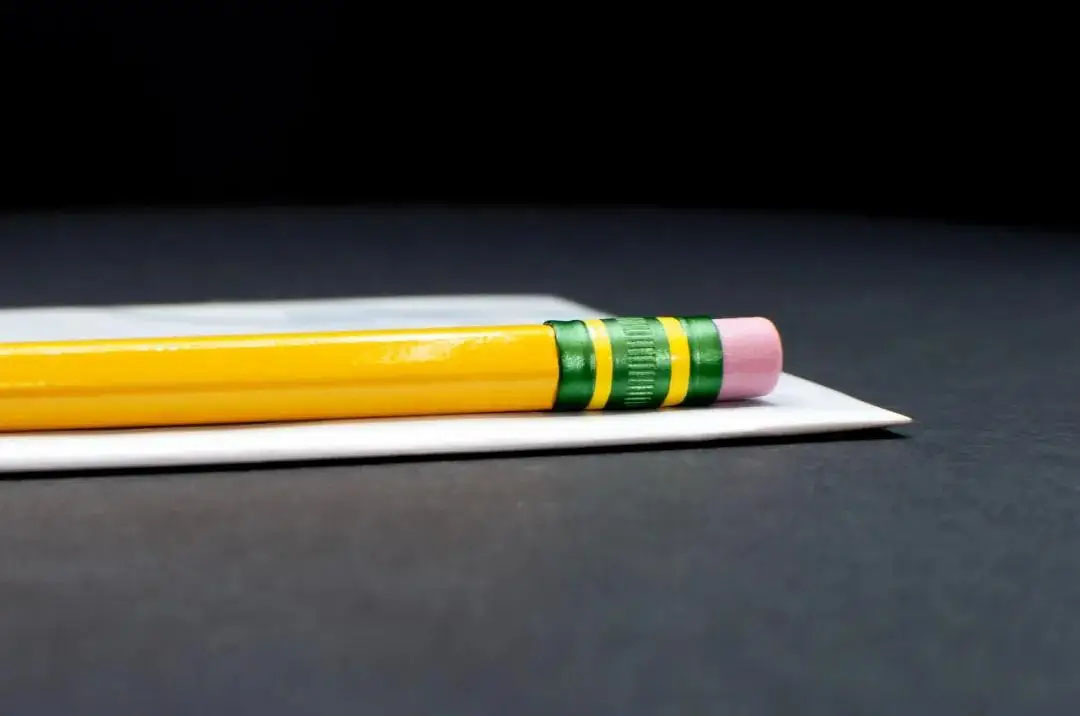

The thickness of the thermal barrier material is usually between 1 and 4 millimeters and can be placed between battery cells. According to different car manufacturers and models, the cost of using this material is approximately $300 to $1000 per vehicle.

Place a pencil on the insulation layer to display its relative thickness

The market is growing rapidly. When we first started selling battery materials in 2021, the annual sales revenue was 7 million US dollars. By 2023, this number has increased to $110 million, and it is expected that sales will double again by 2024.