NEWS&EVENT

Quality is our core our concept

Application of Nano-fumed Silica in Composite Insulators

Release time:

2024-12-03 00:00

Source:

Pollution flashover refers to the phenomenon that dust particles and other substances in the atmosphere deposit on the surfaces of insulators that have been operating outdoors for a long time, gradually forming a pollution layer. Under meteorological conditions such as light rain, snow, fog, haze, and dew, the pollution layer gradually gets wet, and the soluble substances in it gradually dissolve in water, forming a conductive film on the surface of the insulator. This increases the surface conductivity and reduces the insulation performance, resulting in flashover and discharge on the wet surface of the insulator.

An insulator is an electrical component whose main function is to isolate the electrical connection between conductors and supporting structures, preventing current from leaking through the supporting structures or causing arc faults. Reasonable selection and use of insulators are crucial for ensuring the safe and stable operation of power systems. Among them, composite insulators have a high cost-performance ratio due to their characteristics such as strong pollution resistance, high strength, light weight, and being not easily broken, which conforms to the trend of green development.

The insulating parts of composite insulators are composed of glass fiber resin core rods, silicone resin sheaths, and sheds (which play a key role in insulation performance and anti-pollution performance). Composite insulators are equivalent to putting "protective clothing" on transmission line equipment, reducing the impact of different harsh or corrosive environments on the electrical and mechanical properties of transmission systems, further reducing the failure rate of power systems, decreasing the possibility of pollution flashover accidents, saving operation and maintenance costs, and improving the utilization rate of electric energy.

Then how does fumed silica play its role? Relevant research and experiments have been carried out by technical personnel.

Fumed silica mainly plays the roles of thickening and thixotropy in composite insulators and anti-pollution flashover coatings, and can improve the physical and mechanical properties, hydrophobicity, electrical properties and so on of anti-pollution flashover coatings.

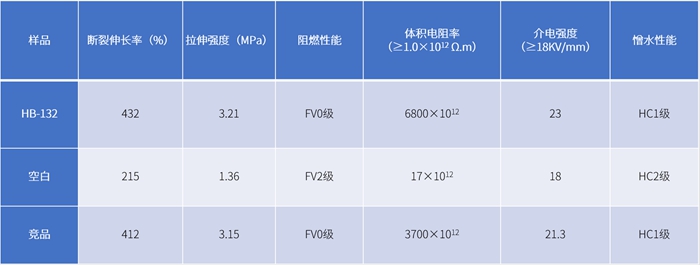

To verify the specific improvement effect of fumed silica on composite insulators, the technical personnel of Huifu Nanotechnology respectively prepared three groups of samples, namely the blank sample (without fumed silica), the experimental sample (with the addition of hydrophobic fumed silica), and the competing product samples. Then they respectively tested the differences among them in elongation at break, tensile strength, flame retardancy, dielectric strength and hydrophobicity, and obtained the data results shown in Table 1.

Through experimental comparison, fumed silica can effectively enhance the physical properties of composite insulators, strengthen their flame retardant and hydrophobic properties, and improve volume resistivity and dielectric strength. Compared with competing products, the hydrophobic fumed silica has certain advantages in observed data and properties.

After adding fumed silica, composite insulators, relying on their excellent hydrophobicity, anti-pollution flashover ability, high electrical insulation, and strong corrosion resistance, provide multiple functions such as electrical insulation, mechanical support, and environmental adaptability, ensuring the safe, stable, and reliable operation of transmission lines and further facilitating the development of clean energy.