NEWS&EVENT

Quality is our core our concept

The Newly-prized Material: Aerogel Material

Release time:

2025-03-12 00:00

Source:

Aerogel is a three-dimensional networked nanoporous material. Its porosity can reach over 90%, the specific surface area can reach 900 m²/g, and the density can be as low as 0.002 g/cm³, making it the solid with the lowest density up to now. The thermal conductivity of aerogel is approximately 0.013-0.018 W/(m·K), and it is an excellent thermal insulation material. It can be used as cold protection and heat insulation materials as well as thermal protection materials, and applied in fields such as aerospace and special protection. Since its invention in 1931, aerogel has undergone an evolutionary process from oxide aerogel to non-oxide aerogels such as carbon aerogel, carbide aerogel, and boride aerogel, and from single-component SiO₂ aerogel to multi-component aerogels such as SiO₂-ZrO₂, SiO₂-Al₂O₃, and SiO₂-PF.

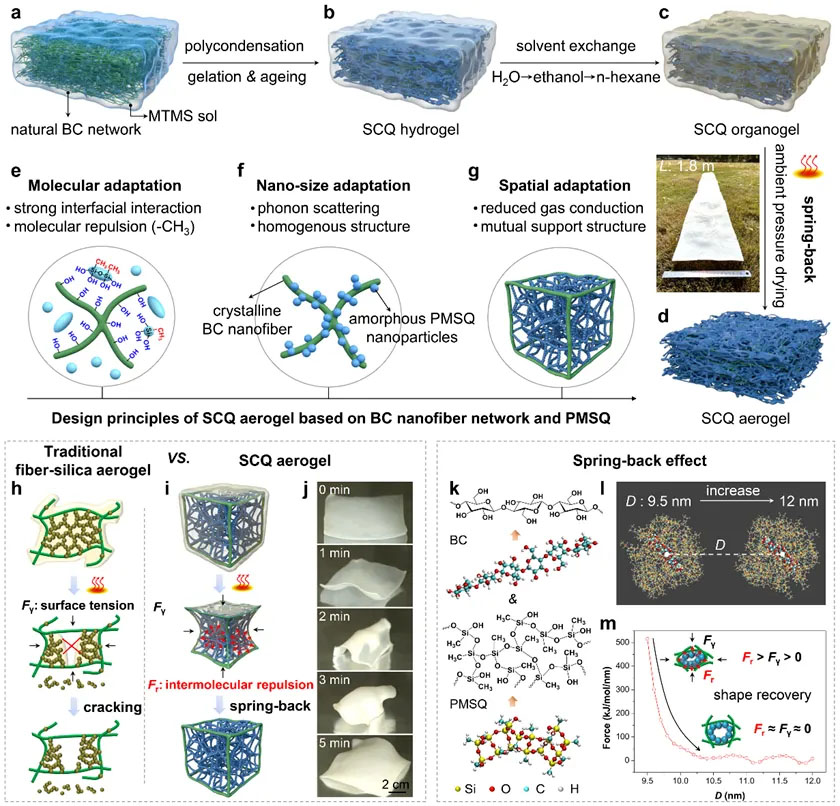

Currently, a kind of nanocomposite aerogel that can be used for thermal protection in extreme environments has been developed. Using the network of lamellar bacterial cellulose nanofibers as a template, the in-situ generation of the mesoporous polysiloxane network is induced, and a shell-like nanocomposite aerogel with the structure of "porous bricks and fibers" is obtained. This aerogel material has excellent thermal insulation performance, with a thermal conductivity as low as 17.4 mW/(m·K). At the same time, it also has excellent mechanical properties, showing high rigidity, super elasticity, high bending flexibility, and good impact resistance. In addition, this aerogel material still exhibits excellent structural stability under extreme temperature conditions. The combination of excellent thermal insulation performance and mechanical properties makes this material a good choice for thermal protection in extreme environments, and it is expected to be applied in spacecraft and spacesuits.

Currently, a kind of nanocomposite aerogel that can be used for thermal protection in extreme environments has been developed. Using the network of lamellar bacterial cellulose nanofibers as a template, the in-situ generation of the mesoporous polysiloxane network is induced, and a shell-like nanocomposite aerogel with the structure of "porous bricks and fibers" is obtained. This aerogel material has excellent thermal insulation performance, with a thermal conductivity as low as 17.4 mW/(m·K). At the same time, it also has excellent mechanical properties, showing high rigidity, super elasticity, high bending flexibility, and good impact resistance. In addition, this aerogel material still exhibits excellent structural stability under extreme temperature conditions. The combination of excellent thermal insulation performance and mechanical properties makes this material a good choice for thermal protection in extreme environments, and it is expected to be applied in spacecraft and spacesuits.

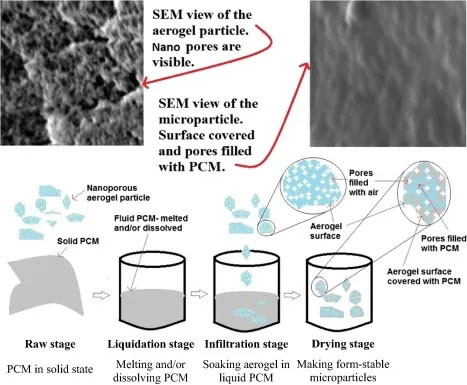

Researchers have combined aerogel with phase change materials (PCM) to improve the thermal protection performance of PCM fire-fighting suits. By coating silica aerogel particles and PCM powder on the thermal insulation layer of the fire-fighting suit, compared with the ordinary PCM thermal insulation layer, the average ignition time has increased from 3.3 seconds to 5.5 seconds, slowing down the flame spread rate. At the same time, the weight of the fabric of the thermal insulation layer has been reduced, and the movement comfort of the fire-fighting suit has been improved. The team has also carried out a series of studies on the application of aerogel nonwoven materials in thermal protective clothing. It has been found that when aerogel nonwoven materials are used as the thermal insulation layer of thermal protective clothing, their heat resistance is five times that of the ordinary thermal insulation layer.

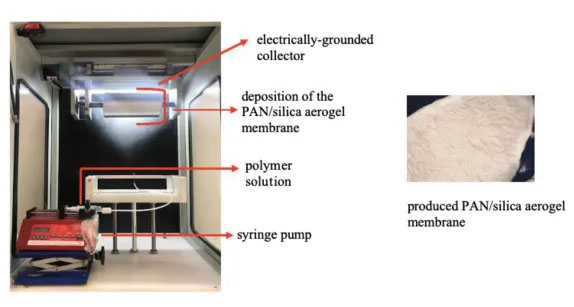

Researchers have used the electrospinning method to add different contents of silica aerogel into polyacrylonitrile nanofibers to prepare a polyacrylonitrile-silica aerogel membrane, which is then used for the waterproof and breathable layer of fire-fighting suits. Compared with traditional materials for the waterproof and breathable layer, this material has improved thermal comfort and thermal protection performance.

It is reported that a company has prepared a kind of polyimide aerogel with very high strength, which is 500 times stronger than SiO₂ aerogel. It is not easy to break or generate dust and has been used in NASA spacesuits.

At the present stage, the application of aerogel in thermal protection textiles is still restricted by its weaknesses such as poor mechanical properties and low thermal stability. Breaking through the key technologies for aerogel preparation, reducing the manufacturing cost, and improving its mechanical properties and thermal stability while maintaining the structural properties of aerogel will be the problems that relevant researchers need to overcome. In other words, there is still a great deal of room for the research and application expansion of aerogel materials.